SIMBA#

Simulation softwareSIMBA# – Fields of application

Fields of application

- Design of wastewater treatment plants taking into account numerous process options including control

- Optimisation of process design and operation of existing wastewater treatment plants

- Analysis of runoff patterns in urban areas

- Development and testing of strategies for sewer network management or sewer network control

- Analysis of the interaction of wastewater discharge, wastewater treatment, sludge treatment and water quality in receiving water bodies

- Analysis of process water management, sludge treatment and energy consumption

- Planning of the use of “digital twins“

- Design of any biogas plant concepts including control

- Virtual commissioning of automation solutions in the water sector

- Mapping and analysis of the complex interactions of the water, energy, waste and food systems (“water-energy-food nexus”)

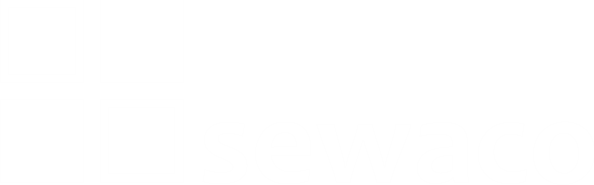

Wastewater treatment plants

With the ever-increasing requirements in the area of planning and operational management of wastewater engineering plants, SIMBA# is pursuing the goal of supporting classic design methods in these areas with the tool of simulation. For the area of wastewater treatment plants, this is expressed by a close link of the DWA-A131 design guidelines with the mathematical activated sludge models ASM3 (Activated Sludge Model No. 3) and ASM3biop as well as the modules available in SIMBA# for individual process steps (e.g. denitrification, nitrification, secondary sedimentation).

Model of a wastewater treatment plant with pre-denitrification in SIMBA#

Fields of application

In the field of wastewater treatment, SIMBA# can be used, for example, as a tool to support the following tasks:

- Design of plants, processes and control concepts,

- Optimisation of process design and development of concepts for the energy management of wastewater treatment plants,

- Development of model-based operation management concepts (observer, MBPC), which can also be used in an online version together with the open-source development ifakFAST for the operation of real plants.

Reactor and activated sludge models

A wide range of combinations of transport and reactor models and activated sludge models is available for the simulation of wastewater treatment plants. Transport and reactor models include modelling blocks for the description of an activated sludge mixture in reactors with intensive mixing and/or aeration by surface aerators and pressurised aeration systems, as well as primary and secondary clarifiers. Tank cascades and batch reactors are also available. Independently of these reactor models, it is possible to choose which activated sludge model the user wishes to work with. Such an activated sludge model defines a number of substance groups of wastewater constituents and microorganisms as well as a number of chemical and biological processes that are considered important for the respective processes.

For the description of the degradation of organic contaminants (COD) and the removal of nitrogen (nitrification/denitrification), for example, the standard models ASM1 (Activated Sludge Model No.1) and ASM3 of the IWA are available. For planning purposes, the ASM3h and ASM3bioph are available in versions of the Central European Researchers‘ Simulation University Group (HSG), which are compatible with DWA-A131 2016.

Models can be freely edited or modified with an easy-to-use editor in Gujer Petersen matrix notation. The following activated sludge models are included in SIMBA# as default options:

- ASM1h – Standard model of IWA with established modifications to improve applicability, parameters according to HSG,

- ASM3h – Version of the IWA’s ASM3 with parameterisation according to suggestions of HSG,

- ASM3bioph – The IWA’s ASM3 with an EAWAG extension for biological P elimination,

- ASM_inCTRL – Extended model (COD, multistage nitrification/denitrification, bioP) provided by the experts of the inCTRL company,

- ASM_XL_lag – Extended model (COD, multistage nitrification/denitrification, anammox) as a project result of the NoNitriNox project (BMBF).

Model blocks for primary and secondary sedimentation

A range of models of varying complexity is available for mapping settling processes in primary and secondary sedimentation, including:

- 3-layer secondary sedimentation model with variable sludge bed compatible with DWA-A131 (2016),

- Simple primary clarification model according to Otterpohl/Freund with specified COD elimination as a function of residence time,

- Ideal sedimentation tank (ideal solid/liquid separation, no storage tank),

- Ideal sedimentation tank with storage (predefinable solid/liquid separation and simple storage).

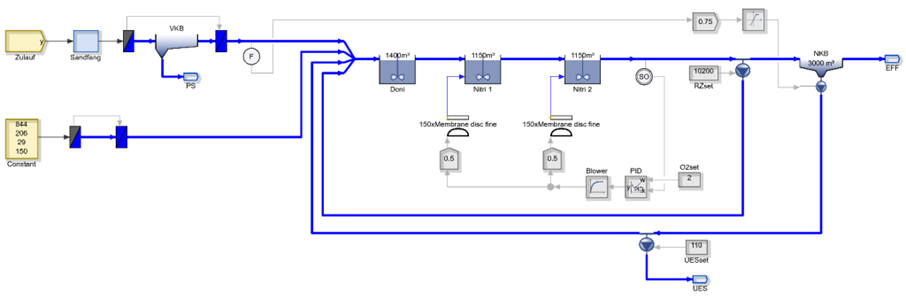

Ventilation system models

SIMBA# also includes detailed models of compressed air ventilation systems. The model library contains components for the description of blowers and blower controls, pipelines with typical installations, control valves (conventional and new developments) and aeration elements (devices for the fine-bubble introduction of air into aeration basins). These components can be interconnected with each other or in connection with a process engineering wastewater treatment plant model. Of course, the function of the automation technology can also be taken into account down to the last detail.

With this extension, it is now possible to

- aeration systems can be designed more energy-efficiently,

- frequent planning errors that lead to unfavourable operating behaviour can be avoided,

- future requirements for strong load fluctuations during extreme rainfall events can be better met,

- energy procurement should be made more flexible (energy management, participation in the energy market),

- Analysing in planning terms how wastewater treatment plants can react more intelligently (Industry 4.0 concepts).

Pressure distribution in a ventilation duct

Sewer networks

SIMBA# offers a high degree of flexibility in the selection of modelling approaches for sewer networks.

Hydrological

- Simplified conceptual modelling

- Rainfall runoff modelling

- Transport pipes in the sewer network

- Tanks and CSO structures according to DWA-A 102/A 128

- Pollution load calculation and long-term simulations

Hydrodynamic

- Complete solution of the Saint-Venant equations

- Import of SWMM models

- Seamless integration and extension of the SWMM5 computational core (see www.epa.gov)

Any combination of both approaches:

In SIMBA#, it is also possible to simulate parts of a sewer network hydrodynamically (e.g. shallow interceptor sewers), whilst a faster hydrological approach can be used for other parts of the same sewer network (e.g. upstream catchments). This allows the complexity of a sewer network model to be set up according to the individual requirements of the respective task.

Each of the two approaches also allows:

- Specification of surface areas according to DWA-A102

- Uniform and non-uniform rainfall

- Arbitrary biochemical transformation processes in the sewers

- Simple and complex control algorithms, including MBPC

- Analysis of the control potential according to DWA-M 180

Overall, SIMBA# enables the seamless integration of the sewer network simulation into models of other subsystems (wastewater treatment plant, rivers).

User-friendly input and output, animation

- User input and output, such as system definition, is graphically supported

- Import of GIS data

- Automatic estimation of pervious and impervious areas from Copernicus satellite data

- Freely configurable evaluation routines allow quick and easy evaluation in text and image form: Sum information (precipitation, runoff and overflow volumes and loads, storage utilisation), discharge durations and frequencies

Rivers

SIMBA# also enables the simulation of flow and water quality in receiving water bodies (rivers). Any biochemical transformation models can be used here. Seamless integration into sewer network and sewage treatment plant modules as well as control algorithms are also possible here.

Discharge calculation

- Hydrological discharge calculation

- Hydrodynamic discharge calculation

Quality models

- Pollutant transport approaches: CSTR and Lagrange

- Biochemical transformation processes freely definable by the user in any complexity

- Predefined models (e.g. SWQM, RWQM1)

Applications

- River water quality simulation

- Analysis of discharges from the sewer system and sewage treatment plant, including evaluation according to the guideline for the analysis of ecologically critical water pollution of the German federal state of Hesse

- Integrated control

- Sequential and parallel integrated simulation

Evaluation: DWA-M 102-3/BWK-M 3-3, Urban Pollution Management Manual

New evaluation routines for water quality simulation with tabular and graphical output:

- Frequency-duration limits for oxygen and ammonium (“matrices of nine”) according to DWA-M 102-3/BWK-M 3-3 and British Urban Pollution Management (UPM) Manual

- Freely configurable textual and graphical output

- Plot of longitudinal profiles

- Time-location diagrams -> Everything at a glance!

- Discharge and water quality

Anaerobic processes

The modelling of anaerobic processes (anaerobic wastewater treatment, sewage sludge digestion) has received more attention since the ongoing demands for energetically optimal operation. The use of anaerobic models is further driven by current developments in the biogas sector. The sub-libraries digestion, Biogas and Advanced Reactors are suitable for modelling plants for anaerobic sewage sludge digestion, anaerobic wastewater treatment and anaerobic digestion of organic matter.

For this purpose the library contains:

- various anaerobic models (ADM1, Siegrist, simplified approaches),

- pre-sedimentation blocks with sludge removal,

- blocks for mechanical thickening and dewatering,

- anaerobic reactor blocks (overflow reactor, storage tank) with gas phase, UASB,

- interface models for coupling with activated sludge models,

- integrated modelling of wastewater treatment and sludge treatment.

Anaerobic models enable the predictions of:

- COD, TS degradation,

- gas production/gas composition (carbon dioxide, methane, hydrogen),

- organic acids and pH value.

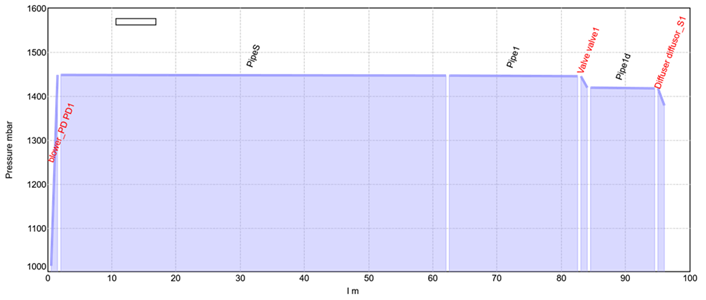

Biogas plants

SIMBA# provides all the necessary components required for a sound analysis of wet fermentation plants. The solution includes explicit reactor models, a multi-substrate anaerobic model based on the ADM1 (Anaerobic Digestion Model No. 1 of the IWA) as well as a corresponding model for the inflowdescription. SIMBA# can be used to realise a wide range of applications in engineering practice, research and teaching. These include the design of biogas plants, processes and control concepts and the optimisation of process design. Further fields of application and features include the following:

- Design of any biogas plant concepts including control,

- Optimisation of feeding and operation management of existing biogas plants,

- Provision of different concepts for modelling measurment and control concepts (classical function blocks, Petri nets, PLC code),

- Prediction of COD, TS, oTS, NH4, N, pH, CH4, FOS, TAC (estimation),

- Convenient editors for biochecmial process models.

Model of a biogas plant including gas system and CHP unit

Pressure pipe networks

In SIMBA# 5.0, a new block library for modelling of pressure pipe networks was introduced. The corresponding model library can be used to simulate pressure and flow rates and mass transport in fully filled pipeline networks. This library is suitable for modelling:

- Drinking water networks,

- wastewater pressure pipelines, (wastewater pumping stations, pressure sewers),

- pumped wastewater transport in wastewater treatment plants,

- service water systems.

For the calculation of the pipeline network, a special solver is used (use of the multisolver approach), which was developed for SIMBA# based on the EPANET solver. The network calculation allows the consideration of pressure-dependent consumption (PDD) and leakages. For mass transport (advection-dispersion), either a continuously stirred tank reactor approach (cascade of CSTRs) or a Lagrangian approach can be selected. If required, also quality processes can be calculated (SIMBA ASM model).

Industrial water systems

Due to increasing water scarcity, the reuse of industrial water and a more efficient use of material and energy resources are playing an increasingly important role in the planning and operation of industrial water systems. SIMBA# offers the possibility to simulate both the distribution and the treatment processes of industrial water and cooling water systems and to optimise their operation with regard to energy and resource consumption.

The fields of application and features include, but are not limited to, the following:

- Cooling water circuits and the balancing of heat flows,

- Accumulation of chemicals in recirculation systems and estimation of blowdown volume,

- Specific service water matrix and modelling of desalination processes,

- Generation of dynamic operating data for Life Cycle Assessment and Life Cycle Costing.